Empowering Welding Industry Since 1967

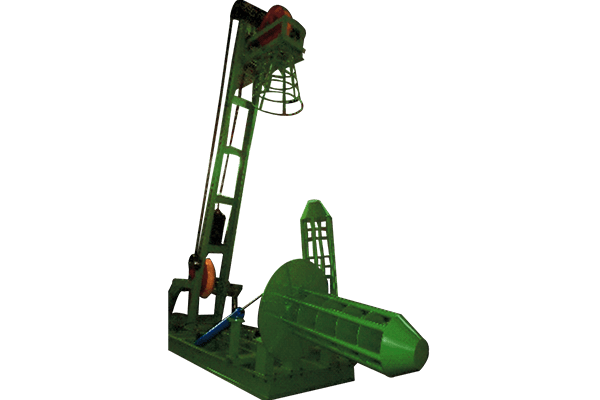

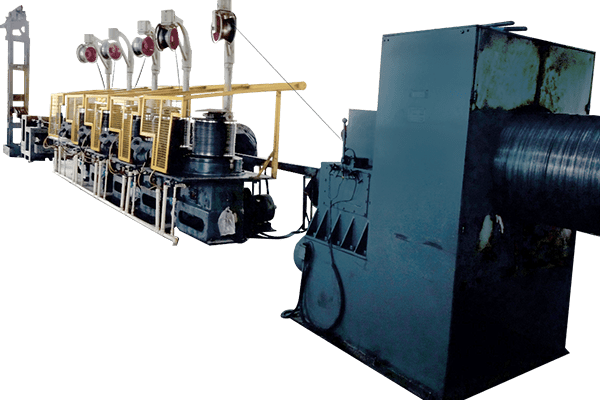

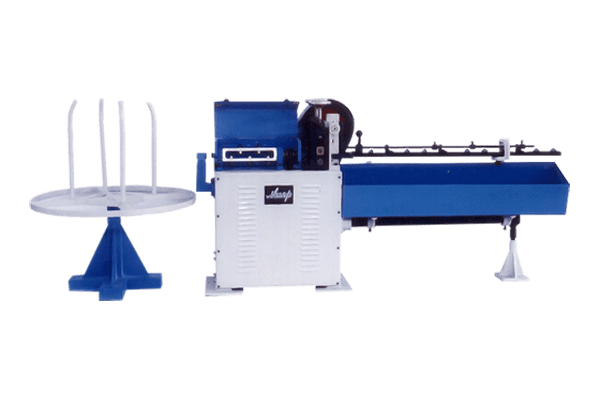

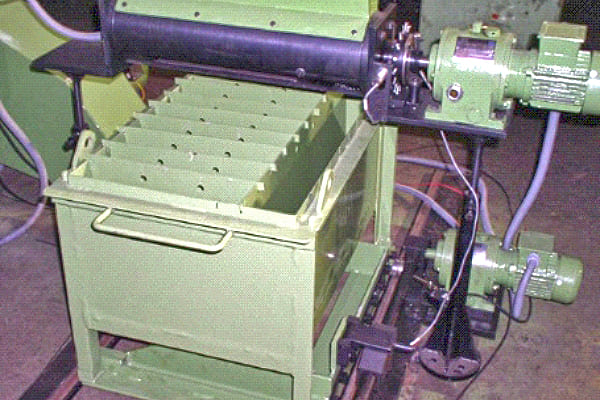

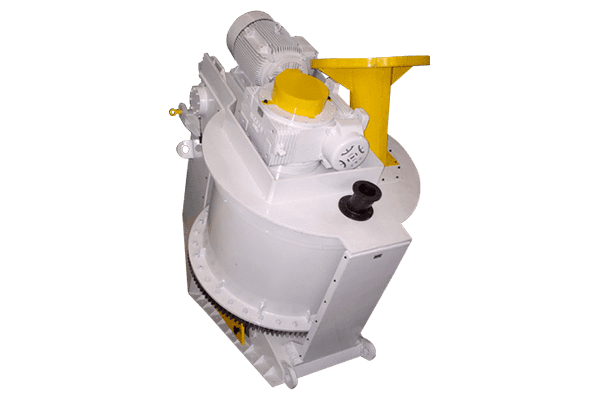

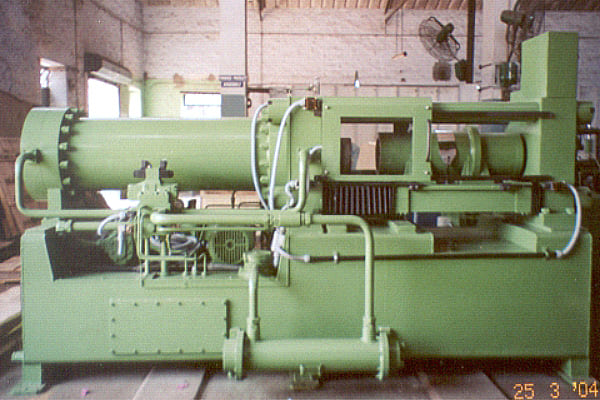

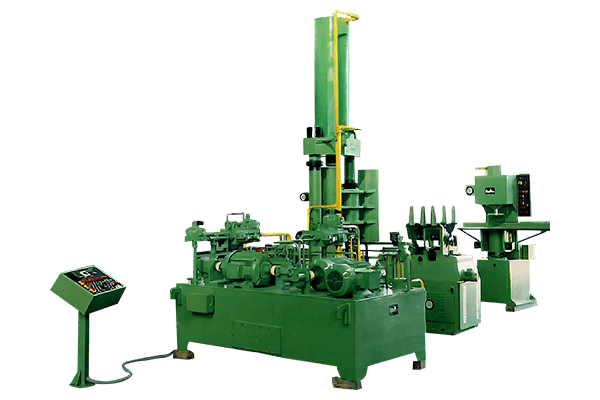

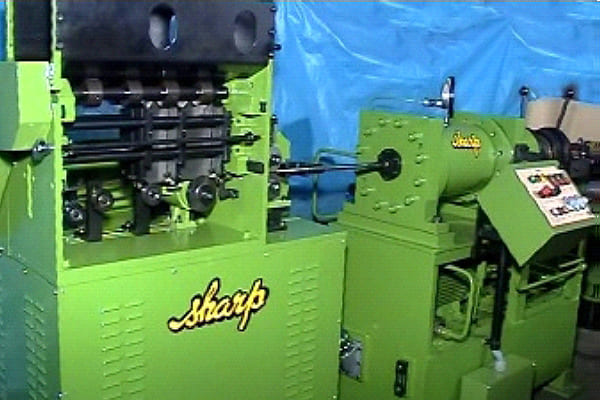

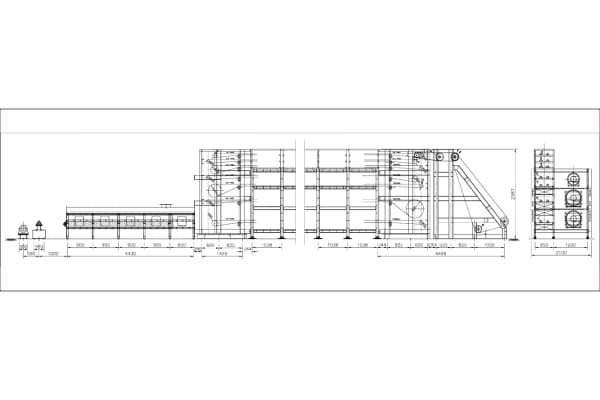

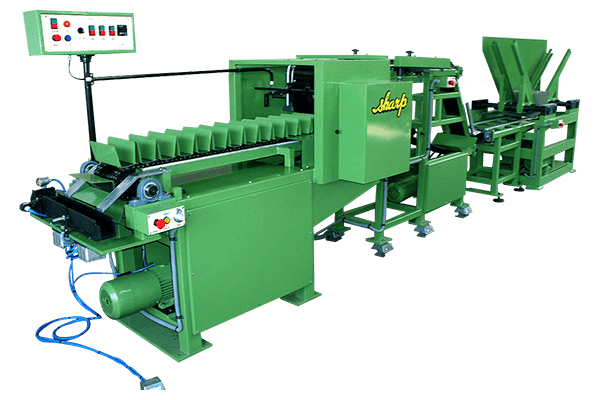

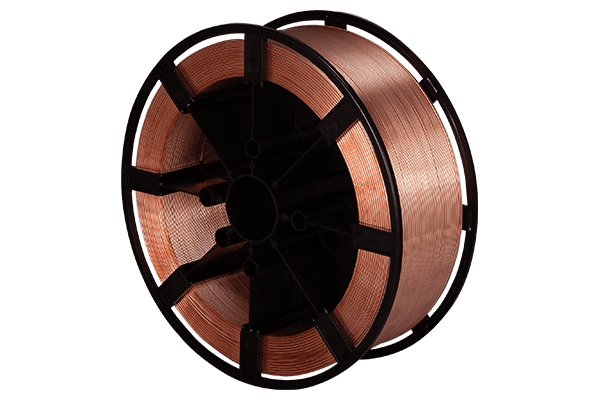

Sharp Tools is a world renowned and globally recognised manufacturer specializing in a wide range of machinery tailored for the production of welding consumables, including Stick electrodes, MIG/MAG wires, SAW flux and wires, and FCW (Flux-Cored Wire) wires.

With a stellar reputation in the industry, Sharp Tools has established itself as a leader in providing high-quality equipment and solutions to meet the demands of welding consumable manufacturers worldwide.

Sharp Tools is a prominent player in the welding consumables machinery manufacturing industry. It is renowned for its cutting-edge technology, global reach, customer-centric approach, and most of all, its commitment to excellence.

With a wide array of machinery solutions and a strong customer base, Sharp Tools continues to add value by contributing to the success of welding consumable manufacturers worldwide.